What Happens After You Tighten a Screw

Why tightening is not a single moment in time.

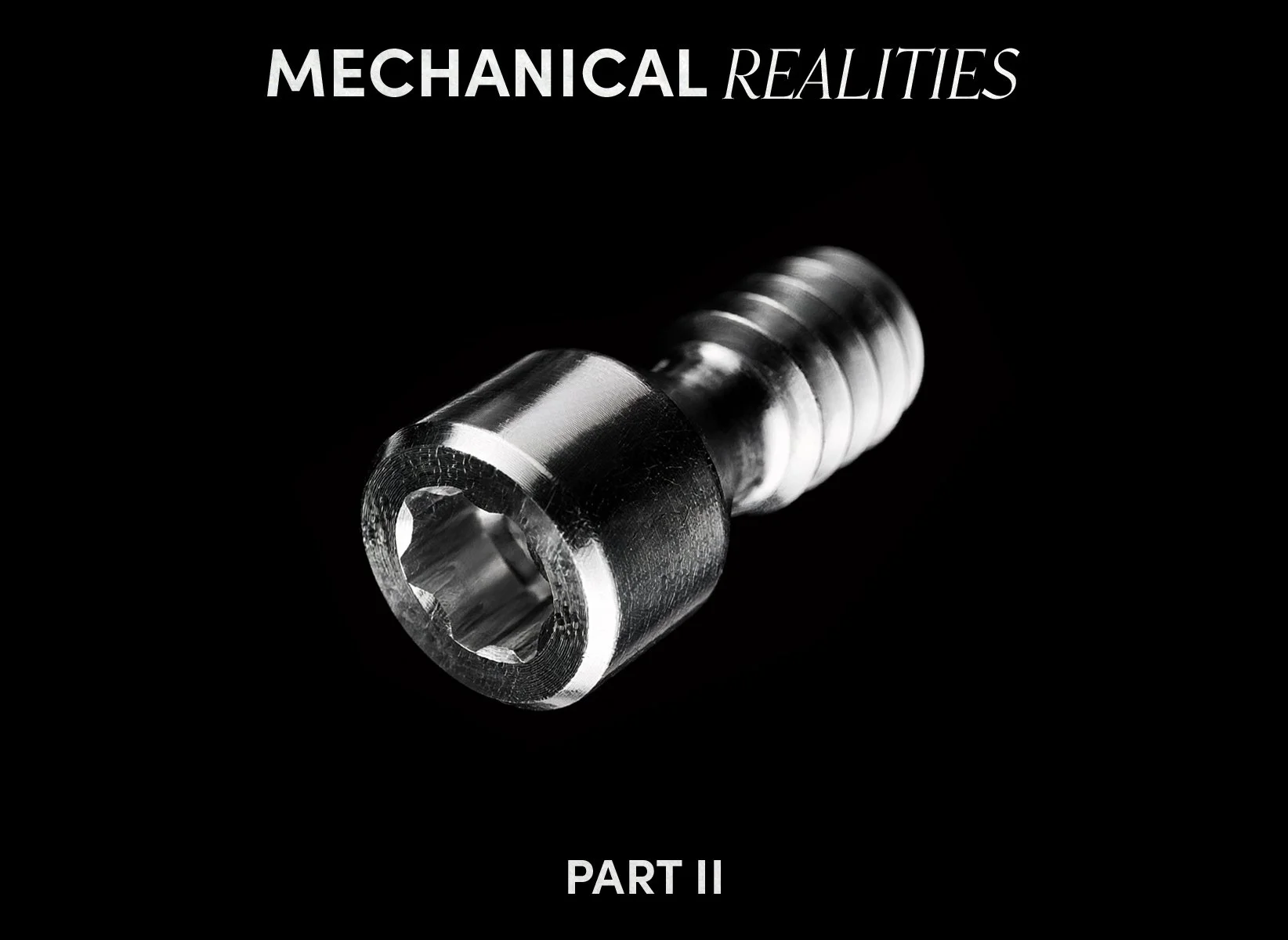

Tightening a screw feels decisive. A value is reached. A click is heard. The moment appears complete. Mechanically, it is not. What happens after tightening is just as important as the act itself.

Tightening Creates Preload, Not Stability

When a screw is tightened, it stretches slightly. That elastic stretch creates preload, the clamping force that holds components together. This preload is what provides stability, not the torque value itself. Torque is simply the method used to create that stretch.

The Settling Effect Begins Immediately

Once preload is established, the interface begins to change.

At the microscopic level:

Thread contact points flatten

Surface irregularities compress

Coatings conform to mating surfaces

This process is known as embedment relaxation, and it begins the moment tightening stops. As surfaces settle, preload decreases, even though the screw has not moved.

Why the First 24 Hours Matter

Studies from mechanical and orthopedic engineering consistently show that the greatest preload loss occurs early, often within the first day.

This loss is not caused by:

Loosening

User error

Material failure

It is a natural result of surfaces finding equilibrium under load. The screw is not backing out. The joint is stabilizing.

Tightening Speed Plays a Role

How a screw is tightened also influences what happens afterward.

When tightening occurs:

Too quickly, materials may not fully accommodate stress

Too slowly, time-dependent deformation (creep) can begin during tightening itself

Both scenarios affect how preload behaves after the fact. This is one reason why two identical tightening events can lead to different long-term outcomes.

Why Retightening Exists

Retightening is not redundancy. It is a response to mechanical reality.

By reintroducing torque after initial settling:

Lost preload can be partially recovered

Interface contact becomes more uniform

Long-term stability improves

This is not about adding force. It is about restoring what naturally diminished.

What This Means Clinically

Understanding post-tightening behavior explains several common observations:

A screw that feels different on re-engagement

A joint that feels more stable after a second tightening

A system that performs better when settling is acknowledged rather than ignored

Torque values set limits. Time changes conditions.

The Takeaway

Tightening is not a single event. It is the beginning of a mechanical process. Preload evolves. Interfaces settle. Stability develops over time, not instantly. Recognizing this turns tightening from a moment into a system.